Do You Really Know the DAIKIN V Series Plunger Pump? (1)

——Working principle、Installation、Use

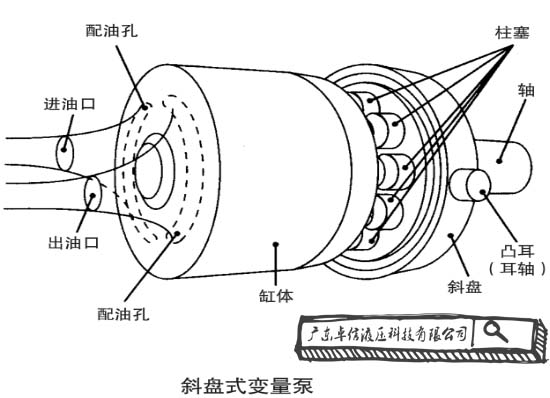

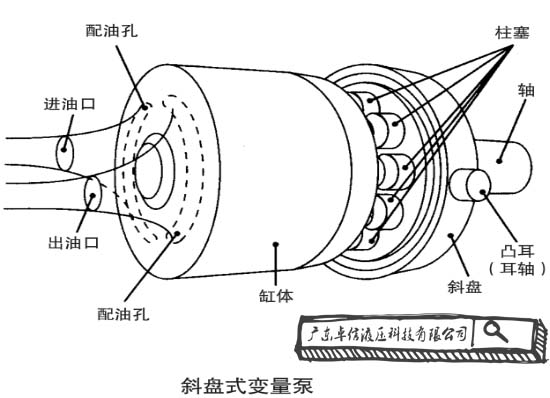

DAIKIN V series piston pump adopts the form of cylinder rotation and end face distribution. When the pump is working, on the one hand, the high pressure oil of the working chamber pushes the cylinder to the oil distribution plate, and on the other hand, the oil film pressure between the oil distribution plate and the cylinder block. Forming a hydraulic reverse thrust on the cylinder causes the cylinder to face away from the oil distribution plate.This series of plunger pumps are designed with a unique design of swash plate angle change function, which is integrated into a system by various control methods. It has the advantages of energy saving, miniaturization and low cost. It adopts special design and not only keeps low in the whole pressure zone. Noise performance, and low power loss, oil temperature rise, can be equipped with a smaller fuel tank. In addition, DAIKIN V series piston pump has high sensitivity and stability, which increases the reliability of the owner.

Let's talk about the working principle of DAIKIN V series plunger pump!

The V-series plunger pump drives the shaft to rotate by a motor, an engine, etc., and a gap is generated between the cylinder and the shoe that the hydraulic pump rotates, and this gap changes with the rotation of the swash plate. The plunger in the cylinder is pushed by the swash plate to reciprocate. This reciprocating motion changes the volume of the plunger chamber and performs operations such as oil absorption and oil discharge.

When the plunger is continuously sucking from the bottom dead center to the top dead center, the working oil enters from the top cover of the terminal and is sucked into the cylinder through the port of the shoe. The oil absorption is proportional to the plunger. In addition, during the stroke of the plunger from the top dead center to the bottom dead center, the working oil is completely forced through the port of the shoe, and finally discharged from the oil outlet of the top cover.

The action of the hydraulic pump is a process of sucking and draining oil every time the cylinder rotates. The rotary drive of the main shaft can be used for continuous oil suction and oil discharge.

I have seen the working principle of DAIKIN V series piston pump, and I have a general understanding of this series of plunger pumps (Please don’t hesitate to contact me if you have any questions), then do you know that it is installed and used? What do you need to pay attention to? How should we use such a pump correctly?

STEP1 Installation

At the beginning of the start-up, it is necessary to confirm whether the direction of rotation of the hydraulic pump is consistent with the direction of the mark on the body, and it is not allowed to enter the full-speed operation at a rapid speed. The motor should be repeatedly turned on/off several times to allow the air in the oil pipe to be discharged before continuous operation. (A sound will appear after the air is completely discharged, and it may not be regarded as an abnormality)

The suction pressure should be kept within -16.7kPa (-125mmHg). If the suction resistance is increased, cavitation will occur, resulting in damage to the device, noise, vibration, and a decrease in life.

STEP2 Use

When connecting with steel pipes, the pump cannot be forced to be eccentric due to the connection piping, and the forced eccentricity caused by the piping may cause abnormal noise. The drain pipe should be connected to the fuel tank independently and should be located below the fuel tank level. The installation location should also be as far as possible from the suction pipe.

Before the pump is started, the pump casing is filled with oil and then restarted. The working oil should be injected from the oil filling port of the pump casing, and the working oil is the same as the oil used in the circuit.

STEP3 Operation

When 7MPa(70kgf/cm

2) or less, normal working oil(R&O) or friction-resistant working oil equivalent to ISO VG32~68 should be used; when 7MPa(70kgf/cm

2) or more, A friction-resistant working oil equivalent to a viscosity grade of ISO VG 32 to 68 is required. The pollution of the working oil will cause the failure of the pump and the service life of the pump. Therefore, it is necessary to pay full attention to the pollution management of the working oil, and the pollution degree should be kept within the NAS9 level.

The eccentricity of the drive shaft and the pump shaft should be less than or equal to TIR 0.05mm. Do not apply a force in the right direction to the pump shaft during operation. If the shaft center is inconsistent, the bearing and oil seal may be damaged, causing noise, vibration, and accidents caused by the pump. At the same time, it is necessary to avoid the noise generated by the lateral rotation of belts, chains and gears and cause bearing damage.

In this issue, we understand the working principle of the DAIKIN V series piston pump, and also understand some of the precautions for its installation and use, which means that we have already got to know such a pump, and the next article will update this. A series of plunger pump

Common Fault Handling , but also want to know other information about this series of plunger pumps, please don’t hesitate to contact me if you have any questions.